Infor SyteLine (CloudSuite Industrial) APS is an advanced planning and production scheduling (APS) solution that creates realistic schedules based on material availability and current production capacity utilisation, allowing you to deliver your product to your customer on the promised date.

Key Features

- Advanced planning and scheduling technology for realistic simulation of the entire production process according to lean manufacturing principles

- Incorporates over 20 years of experience of the world’s leading manufacturing companies

- Fast advances in features and in user-friendliness thanks to the strong development background of Infor as an international company

- Delivery date verification and the ability to schedule an order immediately upon receipt (CTP function)

- Accounting for inventories, including safety stocks, while recognising purchase orders and requirements already issued

- Planning for limited capacities with the possibility of setting the time horizon for resource constraints

- Ordering of operations according to definable rules for individual work centres

- Processing of scheduling alternatives (What-if?) and a tool to compare them

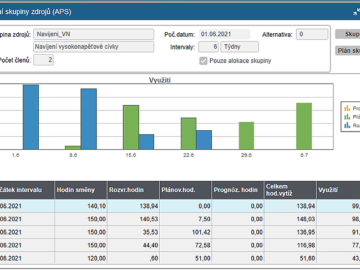

- Displaying the plan and schedule in the form of a Gantt chart with the possibility of operational changes to the plan

The Infor SyteLine (CloudSuite Industrial) APS advanced planning and scheduling tool enables businesses to make the most of their production resources. Thanks to advanced planning and scheduling, companies can adjust production according to changing customer demand and can also verify and confirm realistic delivery dates in advance. The functionality draws on more than 20 years of experience and requirements of a number of world-class manufacturers and on Infor‘s strong commitment to development as an international software company. The biggest advantage of APS is that management gets advance information about anticipated obstacles to meeting the delivery date.

The system thus gives maximum time to address the causes of the expected delay. In doing so it considers the availability not only of materials (and utilisation of human and machine capacity) but also of other definable resources such as tools, moulds and jigs or space required to execute the job. All resources can be set, depending on their nature, as constrained or unconstrained. The Infor SyteLine (CloudSuite Industrial) APS gives the best results when existing bottlenecks are set as constraints.

What the Infor SyteLine (CloudSuite Industrial) APS Is Capable of

The Infor SyteLine (CloudSuite Industrial) APS can plan (Advanced Planning) and schedule (Scheduling) the factory’s production capacity effectively – machinery and workers, availability of moulds, tools and other capacity resources – simultaneously with material planning. By optimising the order flow and increasing throughput, it can increase production capacity by up to 25%. It facilitates the immediate verification of the feasibility of the requested delivery date upon receipt of an order, showing the reasons for any delays, setting a new realistic date or providing information on the quantity that can be delivered on the requested date. The tool can schedule an order or job order as well as a quote or draft job order. Through realistic simulation of the entire manufacturing process, it shows how changes in scheduling and changes in management decisions will affect the company’s situation. It also gives businesses the flexibility to adjust production to changing demand or requirements. A useful feature is drafting multiple plan variations (What-if?) in order quickly to resolve unexpected or problematic situations.

Who the Infor SyteLine (CloudSuite Industrial) APS Is for

Manufacturing companies tend to get into a stage in their development where the methods of production planning and control used so far begin to become increasingly ineffective. They do not provide a realistic plan any more and the plan is highly difficult and time-consuming to prepare. Often, planning is based on the know-how of an individual staff member. Companies are unable to set a delivery date for the customer reliably, work in process and inventory increases, and it gets difficult to keep track of the order status. There is no way to verify the impact of the measures being considered and thus to have a basis for correct decision.

The Infor SyteLine (CloudSuite Industrial) APS is designed to handle such situations, not only saving planners time but also giving them new capabilities and powerful tools. Moreover, it plans on the basis of current data and does not rely on the personal experience of individuals. Every type of production can be planned and scheduled – from custom through piece to mass production.

Why the Infor SyteLine (CloudSuite Industrial) APS

The Infor SyteLine (CloudSuite Industrial) APS is a cutting-edge solution that has been developed since 1999 as part of the Infor SyteLine (Infor CloudSuite Industrial, Infor CSI) comprehensive ERP system oriented towards discrete manufacturing companies. The functionality and benefits of this production planning and scheduling tool have been tried and tested in practice by many companies around the globe. Our experience from dozens of completed projects ensures that these benefits can be achieved in your company as well. The implementation of the Infor SyteLine (CloudSuite Industrial) APS can be a standalone solution to the need for APS planning and scheduling in the form of an add-on to an existing ERP, or it can be part of the implementation of the full Infor SyteLine ERP. It is also possible to add to an existing ERP system APS extended with selected areas of the Infor SyteLine ERP (such as engineering workbench, production control, etc.), which will be of key importance for the planning functionality in the interconnected information solution.

Infor SyteLine (CloudSuite Industrial) APS Features

Ability to set capacities, usually at bottlenecks, as constrained and to set a time limit for this constraint

Notification of material readiness for production – material planning is carried out in parallel with capacity planning, for the time when a given material is needed for a specific operation (JIT)

Developing multiple plan variations to respond flexibly to changing conditions and quickly address the causes of delays, using an alternative material item or resource

Applying different rules in a selected order to individual work centres and selecting the sequence of jobs from the work queue according to these criteria, using standard or user-defined rules

Taking into account the experience and qualifications of staff, assigning one resource to multiple resource groups

The Infor SyteLine (CloudSuite Industrial) APS Explained

Verification of a realistic delivery date upon receipt of an order

The work of the commercial (and customer care) departments is inextricably linked to production and service processes. The Infor SyteLine (CloudSuite Industrial) APS solution enables you to respond flexibly to customer needs and keep them informed of realistic lead times through advanced scheduling with the CTP (capable-to-promise) functionality.

Benefits of the Infor SyteLine (CloudSuite Industrial) APS

- Better capacity utilisation

- Better on-time delivery

- Early notification about expected obstacles

- Reduction of lead times

- Increase in manufacturing throughput

- Fast and correct decision making

- Reduction of work in process

- Reduction of inventory of finished goods

- Reduction of quantities and optimisation of material inventory structure

- Less overtime work

- Speeding up the planning process

- Faster inventory turnover

The Infor SyteLine (CloudSuite Industrial) APS in Customers’ Own Words

"Thanks to all the possibilities SyteLine offers us, we are one step ahead of the competition. The configuration and sophisticated APS planning and scheduling has made us unrivalled in the speed of product delivery to the customer."

"The APS is a tool that has 'opened our eyes' and helps us identify reserves on a daily basis through process indicators. This makes it an indispensable tool for us in the daily improvement process."

"Through implementing the APS planning methodology, we have significantly improved our inventory turnover and reduced the amount of funds we have tied up in inventory. The APS planning methodology also contributed significantly to the 20% increase in turnover we have achieved without having to buy new machines."

References

The Infor SyteLine (CloudSuite Industrial) APS advanced planning and scheduling tool is also used by these companies:

Need a different product?

If your ERP system is at the limits of its capabilities, a total replacement may be a better option than adding an APS module. But we also offer other products to extend any existing ERP:

Infor SyteLine (CloudSuite Industrial) ERP

Information system specifically designed for manufacturing companies

Show me more

Infor LN (CloudSuite Industrial Enterprise) ERP

ERP for large industrial manufacturing, automotive, aerospace and defence companies

Show me more